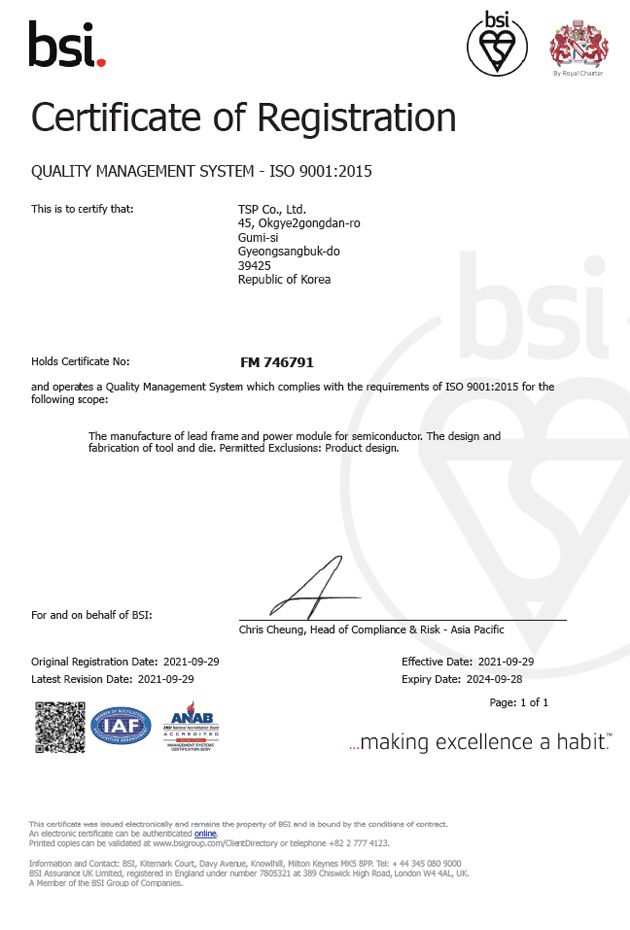

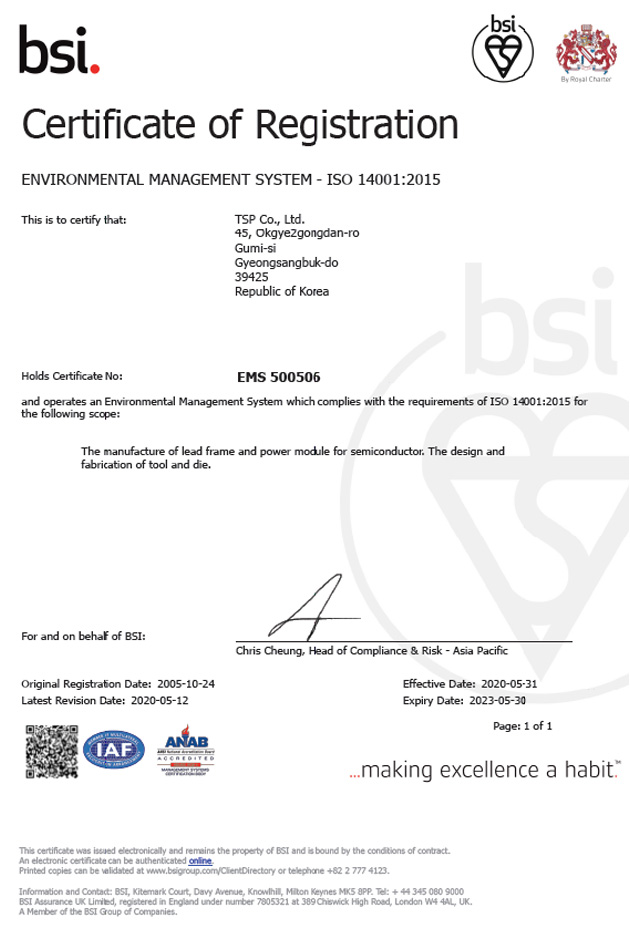

Quality PolicyQuality policy

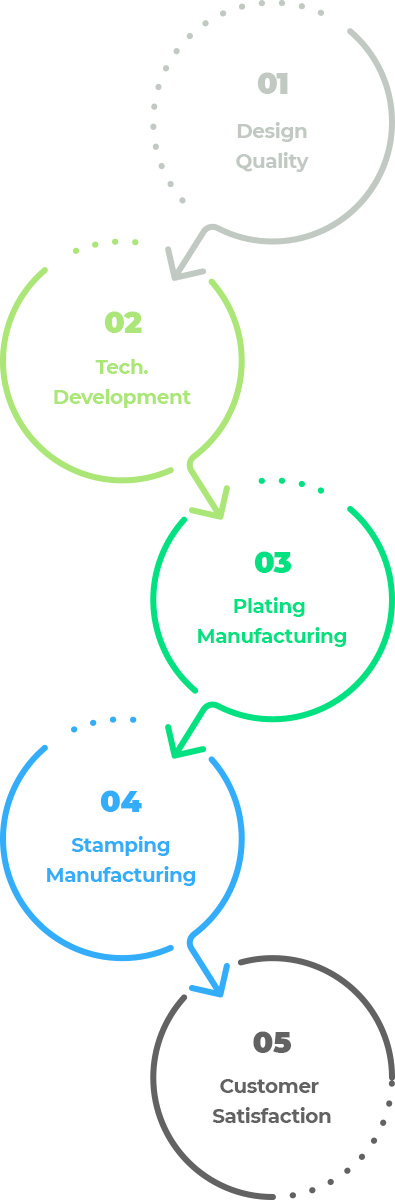

As for the quality management system for quality improvement of TSP, the company establishes an action plan based on the quality policy suggested by Top Management and carries out quality improvement activities.

The company is collecting company-wide quality activities and performances,

reviewing them through quality management meetings, providing improvement plans to top management to reflect them

in the quality policy, and operating a P-D-C-A system for quality improvement to promote continuous quality improvement activities.

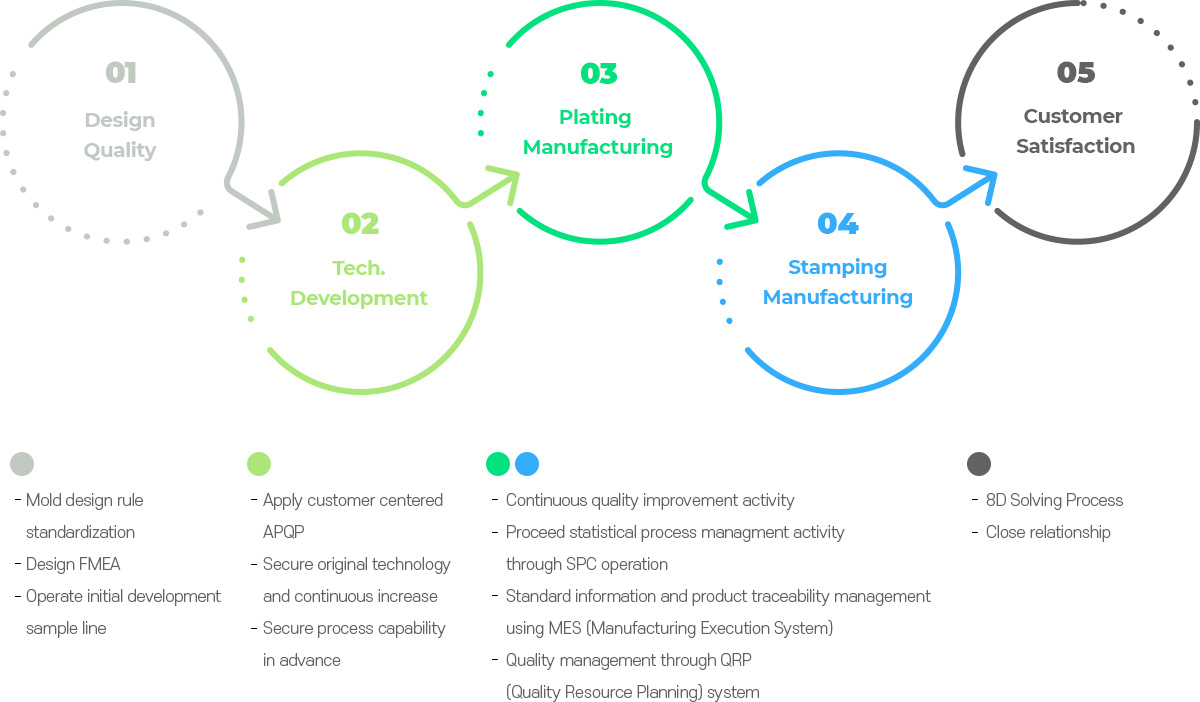

TSP Quality Management System

- Mold design rule standardization

- Design FMEA

-

Operate initial development sample line

(Punching press &

Prototype plating line)

- Apply customer centered APQP

- Secure original technology and continuous increase

- Secure process capability in advance

- System management(Control Plan, FMEA, TPCM)

- Continuous quality improvement activity

- Proceed statistical process managment activity through SPC operation

- Standard information and product traceability management using MES (Manufacturing Execution System)

- Quality management through QRP (Quality Resource Planning) system

- 8D Solving Process

- Close relationship

System

Management

Statistical Process

Control

Measurement System

Analysis

Continuous

Improvement

Change Control Management

PDCA Solving Process

Supplier Quality Management / Periodical Technical Conference with Key Supplier